- RCA 101 – 5-Why Analysis (Free Training)

- RCA201 – Basic Failure Analysis

- RCA 301 – PROACT® RCA Certification

- RCA401 – RCA Train The Trainer

- Other Trainings

- 5 Whys Root Cause Analysis Template

- RCA Template

- Chronic Failure Calculator

Root Cause Analysis with 5 Whys Technique (With Examples)

By Sebastian Traeger

Updated: April 23, 2024

Reading Time: 7 minutes

What Is the 5 Whys Technique?

Example of the 5 whys technique, how to conduct a 5 whys analysis in 5 steps, when to use a 5 whys analysis, using 5 whys template, tips for mastering the 5 whys technique, frequently asked questions about 5 whys.

With over two decades in business – spanning strategy consulting, tech startups and executive leadership – I am committed to helping your organization thrive.

At Reliability, we’re on a mission to help enhance strategic decision-making and operational excellence through the power of Root Cause Analysis, and I hope this article will be helpful!

Our goal is to help you better understand 5 whys techniques by offering insights and practical tips based on years of experience. Whether you’re new to doing RCAs or a seasoned pro, we trust this will be useful in your journey towards working hard and working smart.

The 5 Whys Technique is like peeling an onion – it helps you uncover the underlying reasons behind a problem, layer by layer. By repeatedly asking “why” at least five times, this method digs deep to reveal the root cause of an issue. It’s a simple yet powerful problem-solving approach that aims to get to the heart of the matter rather than just addressing surface-level symptoms.

5 Whys Technique: A method that involves iteratively asking “why” five times to unveil the fundamental cause of a problem.

In essence, the 5 Whys Technique is not just about fixing what’s broken on the surface; it’s about understanding and addressing the deeper issues that lead to problems in the first place.

The 5 Whys Technique is like a detective, uncovering the truth behind recurring problems. Let’s take a look at how this method works in two different scenarios.

Case Study: Manufacturing Defects

Imagine a company that keeps encountering the same manufacturing defects despite various attempts to fix them. By using the 5 Whys Technique, they discovered that the defects were not caused by faulty machinery, as previously assumed, but rather by human error due to unclear operating instructions. This realization led to improved training procedures and clear work guidelines, ultimately eliminating the defects.

Application in Service Industry

Now, consider a service industry struggling with frequent customer complaints and service failures. Through the 5 Whys Technique, it was revealed that these issues stemmed from inadequate staffing levels during peak hours. By addressing this root cause, such as hiring additional staff or adjusting schedules, the service quality can significantly improve, leading to higher customer satisfaction.

These examples illustrate how the 5 Whys Technique can be applied across different sectors to identify and address underlying issues effectively.

Step 1: Identify the Problem

Before diving into a 5 Whys analysis, it’s crucial to clearly identify the problem or issue at hand . This step sets the stage for the entire process and ensures that the focus remains on addressing the right concern. Take the time to gather relevant data, observe patterns, and consult with team members or stakeholders to gain a comprehensive understanding of the problem.

Step 2: Ask ‘Why’ Five Times

Once the problem is clearly defined, it’s time to start peeling back the layers. The process involves asking “why” five times, not necessarily limited to five questions but enough to delve deeper into the underlying causes of the problem . Each “why” serves as a gateway to uncovering additional factors contributing to the issue. This iterative approach helps in identifying not just one cause, but multiple interconnected elements that may be at play.

By consistently probing deeper with each “why,” you can reveal hidden complexities and nuances that may have been overlooked initially. This method allows for a more thorough understanding of the situation, paving the way for effective solutions that address root causes rather than surface-level symptoms.

This structured approach encourages critical thinking and enables teams to move beyond quick fixes towards sustainable improvements.

The 5 Whys Technique is a versatile problem-solving approach that can be applied in various scenarios to uncover root causes and drive continuous improvement. Here are two key situations where the 5 Whys Analysis can be particularly beneficial:

Recurring Issues

- The 5 Whys Technique is especially useful when dealing with recurring issues. Whether it’s a manufacturing defect that keeps resurfacing or a persistent customer complaint in the service industry, this method helps identify the underlying reasons behind these repetitive problems. By repeatedly asking “why,” it becomes possible to trace the issue back to its root cause, allowing for targeted solutions that prevent reoccurrence.

Process Improvement

- Organizations constantly strive to enhance their processes and workflows for increased efficiency and quality. When seeking to improve existing procedures, the 5 Whys Technique serves as a valuable tool. By systematically analyzing the factors contributing to inefficiencies or bottlenecks, teams can gain insights into how processes can be optimized at their core. This method enables organizations to make informed decisions about process improvements based on a deep understanding of the underlying issues.

In both cases, the 5 Whys Analysis offers a structured yet flexible approach to delve into complex problems, making it an indispensable tool for driving meaningful change and progress within organizations.

When it comes to conducting a 5 Whys analysis, utilizing a structured template can greatly facilitate the process and ensure a comprehensive investigation into the root cause identification. Using RCA software such as EasyRCA can benefit the team by streamlining your 5-why process. Here’s how organizations can benefit from using a template:

Benefits of Using a Template

- Streamlined Process: A well-designed 5 Whys template provides a clear framework for conducting the analysis, guiding teams through the iterative questioning process. This streamlines the investigation, making it easier to navigate and ensuring that no crucial aspects are overlooked.

- Thorough Investigation: By following a predefined template, teams are prompted to explore various facets of the problem systematically. This ensures that all relevant factors are considered, leading to a more thorough and insightful investigation into the underlying causes.

- Consistent Approach: Templates offer a standardized approach to conducting 5 Whys analyses within an organization. This consistency promotes uniformity in problem-solving methods across different teams or departments, enhancing overall efficiency and effectiveness.

Customizing the Template

Organizations have the flexibility to customize 5 Whys templates according to their specific needs and industry requirements. This adaptability allows for tailoring the template to address unique challenges and incorporate industry-specific considerations. Customization may include:

- Adding Industry-Specific Prompts: Tailoring the template by incorporating prompts or questions relevant to particular industries or types of issues being analyzed.

- Incorporating Visual Aids: Enhancing the template with visual aids such as flow charts or diagrams can help teams better understand and communicate complex causal relationships.

- Iterative Refinement: Regularly reviewing and refining the template based on feedback and evolving organizational needs ensures that it remains aligned with current processes and challenges.

Customizing the template empowers organizations to harness the full potential of the 5 Whys Technique in addressing diverse problems while aligning with their unique operational contexts.

Encouraging Open Communication

In mastering the 5 Whys Technique as a problem-solving method, creating an environment that fosters open communication is paramount. When team members feel comfortable expressing their perspectives and insights, it leads to a more comprehensive exploration of the underlying causes of a problem. Encouraging open communication allows for diverse viewpoints to be considered, providing a holistic understanding of the issue at hand.

By promoting an atmosphere where individuals are empowered to voice their observations and concerns, the 5 Whys analysis can benefit from a rich tapestry of ideas and experiences. This inclusive approach not only enhances the depth of the analysis but also cultivates a sense of ownership and collective responsibility for addressing root causes within the team or organization.

Continuous Improvement Mindset

A key aspect of mastering the 5 Whys Technique is embracing a continuous improvement mindset. Rather than viewing problems as isolated incidents, this approach encourages teams to see them as opportunities for growth and development. By instilling a culture of continuous improvement, organizations can leverage the insights gained from 5 Whys analyzes to drive positive change across various aspects of their operations.

Fostering a mindset focused on continuous improvement entails actively seeking feedback, evaluating processes, and implementing iterative enhancements based on the findings. It involves an ongoing commitment to learning from past experiences and leveraging that knowledge to proactively address potential issues before they escalate. Embracing this mindset ensures that the 5 Whys Technique becomes ingrained in the organizational ethos, leading to sustained progress and resilience in problem-solving efforts.

As we wrap up our exploration of the 5 Whys Technique, let’s address some common questions that may arise regarding this powerful problem-solving method.

What is the primary goal of the 5 Whys Technique?

The primary goal of the 5 Whys Technique is to uncover the root cause of a problem by iteratively asking “why” at least five times. This approach aims to move beyond surface-level symptoms and address the underlying issues that lead to recurring problems.

Is the 5 Whys Technique limited to specific industries or sectors?

No, the 5 Whys Technique is versatile and can be applied across various industries and sectors. Whether it’s manufacturing, healthcare, service, or technology, this method offers a structured yet flexible approach to identifying root causes and driving continuous improvement.

How does the 5 Whys Technique contribute to continuous improvement?

By delving into the fundamental reasons behind problems, the 5 Whys Technique provides organizations with valuable insights for driving continuous improvement. It not only helps in resolving immediate issues but also fosters a culture of ongoing enhancement and development within an organization.

Can the 5 Whys Technique be used for complex problems with multiple contributing factors?

Yes, while initially designed as a simple and straightforward method, the 5 Whys Technique can certainly be applied to complex problems with multiple interconnected factors. By systematically probing deeper into each layer of causality, this technique enables a comprehensive understanding of intricate issues.

I hope you found this guide to 5 whys technique insightful and actionable! Stay tuned for more thought-provoking articles as we continue to share our knowledge. Success is rooted in a thorough understanding and consistent application, and we hope this article was a step in unlocking the full potential of Root Cause Analysis for your organization.

Reliability runs initiatives such as an online learning center focused on the proprietary PROACT® RCA methodology and EasyRCA.com software. For additional resources, visit Reliability Resources .

- Root Cause Analysis /

Recent Posts

A Step-by-Step Guide to Using Root Cause Analysis Tools for Improved Reliability

How to Choose the Right Root Cause Analysis Tool for Your Reliability Program

How to Perform Root Cause Investigations?

Post-Incident Analysis for Enhanced Reliability

Root Cause Analysis Software

Our RCA software mobilizes your team to complete standardized RCA’s while giving you the enterprise-wide data you need to increase asset performance and keep your team safe.

Root Cause Analysis Training

[email protected]

Tel: 1 (800) 457-0645

Share article with friends:

How it works

For Organizations

Join Mindtools

Related Articles

Vulnerable Leadership: The Power of Opening Up

Self-Disclosure

Building Rapport in Coaching

Mindful Listening

Mutual Respect

Article • 11 min read

Getting to the Root of a Problem Quickly

Written by Jonathan Hancock

Reviewed by Cat MacLeod

Let's join Mindtools to have an ad free experience!

5 whys root-cause analysis.

Have you ever had a problem that refused to go away? No matter what you did, sooner or later it would return, perhaps in another form.

Stubborn or recurrent problems are often symptoms of deeper issues. "Quick fixes" may seem convenient, but they often solve only the surface issues and waste resources that could otherwise be used to tackle the real cause.

In this article and in the video, below, we look at the 5 Whys technique (sometimes known as 5Y). This is a simple but powerful tool for cutting quickly through the outward symptoms of a problem to reveal its underlying causes – so that you can deal with it once and for all.

Origins of the 5 Whys Technique

Sakichi Toyoda, the Japanese industrialist, inventor, and founder of Toyota Industries, developed the 5 Whys technique in the 1930s. It became popular in the 1970s, and Toyota still uses it to solve problems today.

Toyota has a "go and see" philosophy. This means that its decision making is based on an in-depth understanding of what's actually happening on the shop floor , rather than on what someone in a boardroom thinks might be happening.

The 5 Whys technique is true to this tradition, and it is most effective when the answers come from people who have hands-on experience of the process or problem in question.

The method is remarkably simple: when a problem occurs, you drill down to its root cause by asking "Why?" five times. Then, when a countermeasure becomes apparent, you follow it through to prevent the issue from recurring.

The 5 Whys uses "countermeasures," rather than "solutions." A countermeasure is an action or set of actions that seeks to prevent the problem from arising again, while a solution may just seek to deal with the symptom. As such, countermeasures are more robust, and will more likely prevent the problem from recurring.

When to Use a 5 Whys Analysis

You can use 5 Whys for troubleshooting, quality improvement, and problem solving, but it is most effective when used to resolve simple or moderately difficult problems.

It may not be suitable if you need to tackle a complex or critical problem. This is because 5 Whys can lead you to pursue a single track, or a limited number of tracks, of inquiry when, in fact, there could be multiple causes. In cases like these, a wider-ranging method such as Cause and Effect Analysis or Failure Mode and Effects Analysis may be more effective.

This simple 5 Whys technique, however, can often direct you quickly to the root cause of a problem. So, whenever a system or process isn't working properly, give it a try before you embark on a more in-depth approach – and certainly before you attempt to develop a solution.

The tool's simplicity gives it great flexibility, too, and 5 Whys combines well with other methods and techniques, such as Root Cause Analysis . It is often associated with Lean Manufacturing , where it is used to identify and eliminate wasteful practices. It is also used in the analysis phase of the Six Sigma quality improvement methodology.

How to Use the 5 Whys

The model follows a very simple seven-step process: [1]

1. Assemble a Team

Gather together people who are familiar with the specifics of the problem, and with the process that you're trying to fix. Include someone to act as a facilitator , who can keep the team focused on identifying effective countermeasures.

2. Define the Problem

If you can, observe the problem in action. Discuss it with your team and write a brief, clear problem statement that you all agree on. For example, "Team A isn't meeting its response time targets" or "Software release B resulted in too many rollback failures."

Then, write your statement on a whiteboard or sticky note, leaving enough space around it to add your answers to the repeated question, "Why?"

3. Ask the First "Why?"

Ask your team why the problem is occurring. (For example, "Why isn't Team A meeting its response time targets?")

Asking "Why?" sounds simple, but answering it requires serious thought. Search for answers that are grounded in fact: they must be accounts of things that have actually happened, not guesses at what might have happened.

This prevents 5 Whys from becoming just a process of deductive reasoning, which can generate a large number of possible causes and, sometimes, create more confusion as you chase down hypothetical problems.

Your team members may come up with one obvious reason why, or several plausible ones. Record their answers as succinct phrases, rather than as single words or lengthy statements, and write them below (or beside) your problem statement. For example, saying "volume of calls is too high" is better than a vague "overloaded."

4. Ask "Why?" Four More Times

For each of the answers that you generated in Step 3, ask four further "whys" in succession. Each time, frame the question in response to the answer you've just recorded.

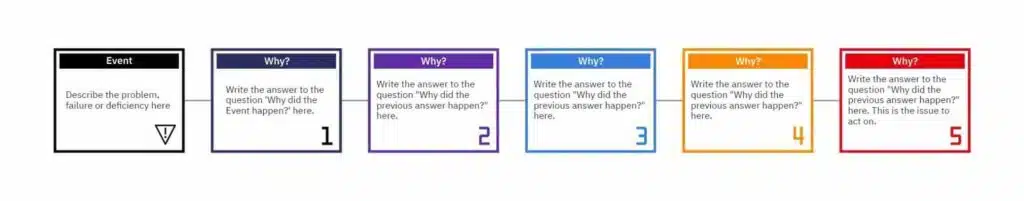

What Is a 5 Whys Template?

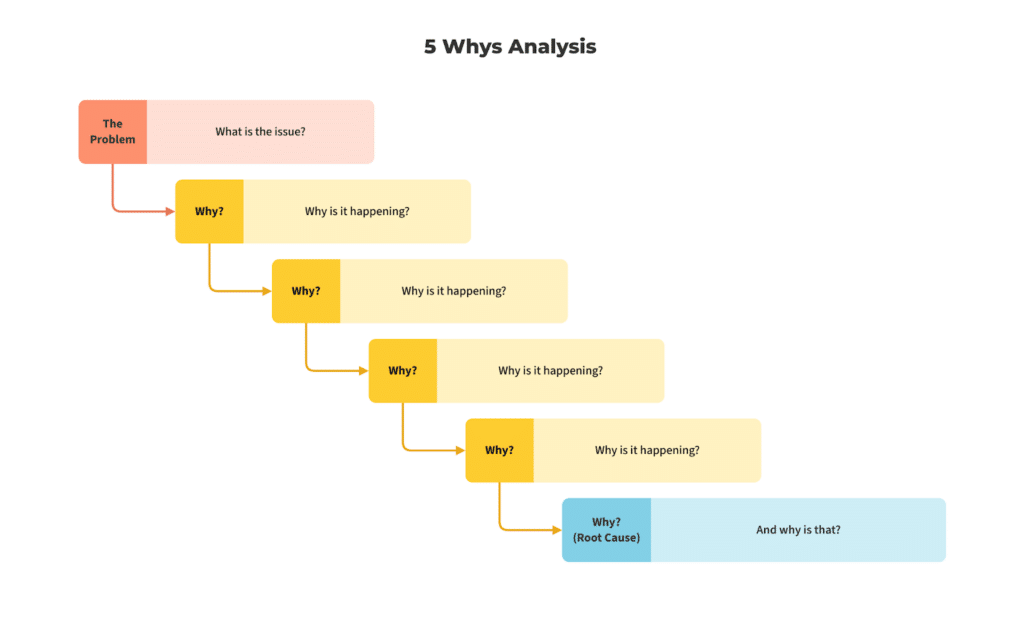

The diagram, below, shows an example of 5 Whys in action, following a single lane of inquiry.

Figure 1: 5 Whys Example (Single Lane)

The 5 Whys method also allows you to follow multiple lanes of inquiry. An example of this is shown in figure 2, below.

In our example, asking "Why was the delivery late?" produces a second answer (Reason 2). Asking "Why?" for that answer reveals a single reason (Reason 1), which you can address with a countermeasure.

Similarly, asking "Why did the job take longer than expected?" has a second answer (Reason 2), and asking "Why?" at this point reveals a single reason (Reason 1). Another "Why?" here identifies two possibilities (Reasons 1 and 2) before a possible countermeasure becomes evident.

There is also a second reason for "Why we ran out of printer ink" (Reason 2), and a single answer for the next "Why?" (Reason 1), which can then be addressed with a countermeasure.

Figure 2: 5 Whys Example (Multiple Lanes)

Step 5. Know When to Stop

You'll know that you've revealed the root cause of the problem when asking "why" produces no more useful responses, and you can go no further. An appropriate countermeasure or process change should then become evident. (As discussed earlier, if you're not sure that you've uncovered the real root cause, consider using a more in-depth problem-solving technique like Cause and Effect Analysis , Root-Cause Analysis , or FMEA .)

If you identified more than one reason in Step 3, repeat this process for each of the different branches of your analysis until you reach a root cause for each one.

6. Address the Root Cause(s)

Now that you've identified at least one root cause, you need to discuss and agree on the countermeasures that will prevent the problem from recurring.

7. Monitor Your Measures

Keep a close watch on how effectively your countermeasures eliminate or minimize the initial problem. You may need to amend them, or replace them entirely. If this happens, it's a good idea to repeat the 5 Whys process to ensure that you've identified the correct root cause.

Appreciation

A similar question-based approach known as "appreciation" can help you to uncover factors in a situation that you might otherwise miss.

It was originally developed by the military to assist commanders in gaining a comprehensive understanding of any fact, problem or situation. But you can also apply it in the workplace.

Starting with a fact, you first ask the question, "So what?" – in other words, what are the implications of that fact? Why is this fact important?

You then continue asking that question until you've drawn all possible conclusions from it.

The major difference between this and the 5 Whys technique is that appreciation is often used to get the most information out of a simple fact or statement, while 5 Whys is designed to drill down to the root of a problem.

Tips for Using the 5 Whys Technique

- Try to move quickly from one question to the next. That way, you'll have the full picture before you jump to any conclusions.

- The "5" in 5 Whys is really just a " rule of thumb ." In some cases, you may need to ask "Why?" a few more times before you get to the root of the problem. In other cases, you may reach this point before you ask your fifth "Why?" If you do, make sure that you haven't stopped too soon, and that you're not simply accepting "knee-jerk" responses.

- Know when to stop! The important point is to stop asking "Why?" when you stop producing useful responses.

Frequently Asked Questions About 5 Whys

1. what is the 5 whys technique.

The 5 Whys Technique is a problem-solving method involving repeatedly asking "why?" It's a way of quickly getting to the root cause of a situation.

2. Who Invented 5 Whys?

The 5 Whys technique was invented in the 1930s by Sakichi Toyoda, the Japanese industrialist, inventor, and founder of Toyota Industries.

5 Whys Infographic

See our infographic on the 5 Whys and use it to get to the root of your problems!

Bear in mind that appreciation can restrict you to one line of thinking. For instance, once you've answered your first "So what?" question, you might follow a single line of inquiry to its conclusion. To avoid this, repeat the appreciation process several times over to make sure that you've covered all bases.

The 5 Whys strategy is a simple, effective tool for uncovering the root of a problem. You can use it in troubleshooting, problem-solving, and quality-improvement initiatives.

Start with a problem and ask why it is occurring. Make sure that your answer is grounded in fact, and then ask the question again. Continue the process until you reach the root cause of the problem, and you can identify a countermeasure that will prevent it from recurring.

Bear in mind that this questioning process is best suited to simple or moderately difficult problems. Complex problems may benefit from a more detailed approach, although using 5 Whys will still give you useful insights.

[1] Pojasek, R. (2000). 'Asking "Why?" Five Times,' Environmental Quality Management , Volume 10, Issue 1, 79–84. Available here . [Accessed July 1, 2022.]

This is your second and last free resource

Enjoy unlimited access to Mindtools

Discover more content

Golden Rules of Goal Setting

Five rules to set yourself up for success

Questioning Techniques

Asking questions effectively

The GROW Model of Coaching and Mentoring

A simple process for developing your people

Building Trust Inside Your Team

Ways to improve team cohesion

Add comment

Comments (0)

Be the first to comment!

Special holiday offer! 30% off subscriptions to Mindtools

With Mindtools, you’ll un wrap practical tools, expert insights and self-paced learning to thrive as a manager and leader.

Sign-up to our newsletter

Subscribing to the Mindtools newsletter will keep you up-to-date with our latest updates and newest resources.

Subscribe now

Business Skills

Personal Development

Leadership and Management

Member Extras

Key Management Skills

Most Popular

Latest Updates

Building a Culture of Belonging

EDI Challenges for Managers

For Individuals

Mindtools Store

Discover something new today

Mindtools member newsletter december 19, 2024.

Let's Get It Done!

Impact Analysis

Identifying the Full Consequences of Change

How Emotionally Intelligent Are You?

Boosting your people skills

Self-Assessment

What's Your Leadership Style?

Learn About the Strengths and Weaknesses of the Way You Like to Lead

Recommended for you

Peter block: the empowered manager.

Taking Control of Office Politics

Business Operations and Process Management

Strategy Tools

Customer Service

Business Ethics and Values

Handling Information and Data

Project Management

Knowledge Management

Self-Development and Goal Setting

Time Management

Presentation Skills

Learning Skills

Career Skills

Communication Skills

Negotiation, Persuasion and Influence

Working With Others

Difficult Conversations

Creativity Tools

Self-Management

Work-Life Balance

Stress Management and Wellbeing

Women in Leadership

Coaching and Mentoring

Change Management

Team Management

Managing Conflict

Delegation and Empowerment

Performance Management

Leadership Skills

Developing Your Team

Talent Management

Problem Solving

Decision Making

Member Podcast

Member Newsletter

Introducing the Management Skills Framework

Transparent Communication

Social Sensitivity

Self-Awareness and Self-Regulation

Team Goal Setting

Recognition

Inclusivity

Active Listening

- Consultancy

- Online Courses

Join our Free Webinar

10th december 2024 | 1pm cet.

- All , Lean Business Model , Lean Management , Lean Wiki

The 5 Why Problem-Solving Technique | Root Cause Analysis

- 7 mins to read

- July 13, 2018

- By Reagan Pannell

By using the 5-why analysis, you can get to the root cause of a problem, rather than just treating its symptoms.n help.

One of the most famous and straightforward problem-solving methodologies introduced by Toyota has become known as the “Five Why’s”. It’s a tool where you simply keep asking “Why” 5 times to identify the root cause of the problem and potentially a simple solution. It’s at the heart of lean thinking and our Lean training courses .

Did you know that kids ask around 90 questions a day and many of them are just “Why”!

We all naturally ask, “Why” all the time? The last figure I heard is that kids ask around 90 questions a day, and many of them are “Why?” style questions.

And the best way to imagine how the ‘Five Whys’ work is to imagine children asking “why”… again and again. As adults, we ask “Why?” once or maybe twice. If you are at a dinner party, asking your friends “Why?” more than twice, may make us look like petulant children. To ask your boss “Why?” once may not even be possible in case it comes across threatening or disrespectful, or perhaps you will feel that its a sign of your lack of knowledge.

But asking “why” without the threatening and undermining tone is an essential way we all began to learn. Asking “why” almost gets kicked out of us at school and with it the questioning mind that we all need if we want to do something different.

VISIT OUR FREE COURSE

Ready to level up your career, lean six sigma courses.

LEAN SIX SIGMA TRAINING

Ready to level up your career, get free access to our certified lean six sigma courses.

The ‘Five Whys’ is this simple in theory.

It asks us to take an open mind to a problem and to not be afraid to keep asking why five times (plus or minus a couple depending on the situation). And what is the goal? Well, our goal is to keep drilling down until we feel that “A-HA!” moment when things suddenly make more sense, and we have uncovered a root cause.

So let’s bring this to life with a real-life example regarding the Washington Monument.

The Washington Monument and others for that matter were deteriorating quite severely in the early ’90s. The specialists were sure why. However, on the desk of Don Messersmith, an esteemed Entomologist (the scientific study of insects) was what has become one of the most famous examples of the five whys approach to problem-solving .

Just for the curious: Messersmith, Donald H. 1993. Lincoln Memorial Lighting and Midge Study . Unpublished report prepared for the National Park Service. CX-2000-1-0014. N.p

Idea Summary: The problem was simple: The Washington Monument in Washington D.C. is deteriorating.

Why #1 – Why is the monument deteriorating? Because harsh chemicals are being frequently used to clean the monument

Why #2 – Why are harsh chemicals needed? To clean off the large number of bird droppings being left on the monument

Why #3 – Why are there a large number of bird droppings on the monument? Because of the large number of spiders and other insects which are a food source of the birds

Why #4 – Why are there large numbers of spiders and other insects around the monument? Because the insects get drawn to the monument at dusk

Why #5 – Why are the insects attracted to the monument at dusk? Because the lighting in the evening attracts the local insects

This classic five why example shows how the goal of the “five why problem-solving” approach is to move past the first level inquiry. It would have been quite easy to change the chemical, which was causing the apparent issue or investigate different cleaning methods which may slow the deterioration but nothing more.

The solution implemented was simply to delay turning on the lights at night. The result was a dramatic 85% reduction in the midges and consequently, a massive drop in bird droppings and the level of cleaning required. The bonus was also a reduction in energy costs.*

Five Why application to Customer / User Experience

The five why problem-solving technique can be used in almost all scenarios where you are trying to resolve an identified problem. So in the example below, let’s look at customer behaviour.

In the book “Hooked (How to Build Habit-Forming Products)”, the author Nir Eyal ( www.nirandfar.com ), uses the five whys approach to dig into users behaviour and tries to identify the underlying root cause of the behaviour. He points out that “one method is to try asking the question “Why?” as many times as it takes to get to anemotion.” The emotion behind the behaviour is often the driving force and the trigger which forms habits.

Idea Summary: Problem: What drives people to use email?

Why #1 – Why would Julie want to use email? So she can send and receive messages.

Why #2 – Why does she want to do that? Because she wants to share and receive information quickly?

Why #3 – Why does she want to do that? To know what’s going on in the lives of her coworkers, friends, and family.

Why #4 – Why does she need to know that? To know if someone needs her.

Why #5 – Why would she care about that? She fears to be out of the loop

While the final “why” appears to point to something very different than the Washington Monument example they both uncover a root cause.

The first example is that the lighting is attracting the midges.

In the second example – its finding the root emotion that drives people to use a particular product and knowing that this emotion can help business connect with their customers at a deeper level to build successful products that a customer wants to engage with.

Here is Edward Bear, coming downstairs now, bump, bump, bump on the back of his head, behind Christopher Robin. It is, as far as he knows the only way of coming downstairs, but sometimes he feels that there really is another way, if only he could stop bumping for a moment and think of it. Winnie the Pooh Tweet

Accelerate success

Level-up today.

Similar Articles

Driving Enterprise Value: A Strategic Operational Transformation in the Events Industry

Visual Management in Digital Workspaces: Enhancing Operations

View all articles, other articles.

17 Benefits of a Lean Six Sigma Certification

Leadership Skills Development Through Lean Thinking

The Importance of Identifying the Right Sample Size for Business Improvement

What is Sigma in Six Sigma, and What Does It Mean for You?

Online Business Courses Free: The Benefits for Professionals

How to Optimize Energy Procurement Strategies for Your Business

Realizing Results: Implementing Change with Precision

Mastering Enterprise Change: Strategies for Successful Transformation

Ready to talk i want to talk to your experts in business transformation so ..., related articles.

Visualizing Change: The First Step to Successful Transformation

Fleet Management: Maximizing Fleet Efficiency for NGOs

Mastering the Seven Wastes of Lean: Strategies for Effective Reduction

Mastering OEE Calculation Example: A Practical Approach to Efficiency

Why Leading Change Programs Often Fail to Deliver Real Change

Mastering Operations Excellence: Strategies for Success and Growth

Using Lean to Improve Decision-Making Processes

Lean six sigma online courses.

FREE COURSE | YELLOW BELT | GREEN BELT | BLACK BELT | MASTERCLASS | WORKSHOPS

Fundamentals of Lean

Ready to start your journey into the world of Lean with this free course?

FREE COURSE

Lean Thinking

A Lean focused continious improvement certification course

LSS Yellow Belt

Propel your career forward, tackle complex problems and drive change

LSS Green Belt

The ultimate fast-track for future leadership

LSS Black Belt

Become an expert in change management and complex problem-solving.

TAKE OUR QUIZ

Which course is right for you.

Take our short quiz to find out which of our courses is right for you.

Join us for a Free Demo

We will talk you through our business transformation & lean training solutions, learn to lead the change.

- SALE ENDS IN:

— NEXT ONLINE WEBINAR STARTS 10th DECEMBER —

Join our webiner 25% off, take our business transformation quiz, are you ready for change.

5 whys: The Power of Asking "Why?" Five Times

The Power of Asking "Why?" Five Times: A Deep Dive into the 5 Whys Method

In any problem-solving process, it's essential to identify the root cause of the issue to solve it effectively. That's where the 5 Whys method comes in.

This simple yet powerful technique involves asking "why?" five times to get to the heart of the problem. By doing so, you can address the underlying cause of the issue and develop long-term solutions.

In this article, we'll explore the 5 Whys method and its benefits. We'll also provide you with practical tips on how to use it effectively in your personal and professional life.

What is the 5 Whys method?

The 5 Whys method is a problem-solving technique that was first introduced by Sakichi Toyoda, the founder of Toyota Industries, in the 1930s. The idea behind the method is to ask "why?" five times in a row to get to the root cause of a problem. Each subsequent "why?" builds on the answer to the previous question, allowing you to delve deeper into the issue.

How does the 5 Whys method work?

Let's say that your car won't start. You might ask yourself, "Why won't my car start?" Your first answer might be, "The battery is dead." You would then ask yourself, "Why is the battery dead?" Your second answer might be, "The alternator is not charging the battery.

" You would then ask yourself, "Why is the alternator not charging the battery?" Your third answer might be, "The alternator belt is broken ." You would then ask yourself, "Why is the alternator belt broken?" Your fourth answer might be,

"The belt was well past its replacement date, and I didn't get it replaced." You would then ask yourself, "Why didn't I get the belt replaced?" Your fifth and final answer might be, "I forgot about it."

By asking "why?" five times, you have identified the root cause of the problem: forgetting to replace the alternator belt. Now you can take steps to prevent this problem from happening in the future.

What are the benefits of the 5 Whys method?

The 5 Whys method offers several benefits, including:

Identifying the root cause of the problem

By asking "Why?" five times, you can get to the heart of the issue and identify the underlying cause of the problem . This allows you to develop effective long-term solutions rather than just addressing the symptoms of the issue.

Encouraging critical thinking

The 5 Whys method encourages critical thinking by forcing you to examine the issue from different angles. It helps you avoid jumping to conclusions and making assumptions.

Promoting teamwork

The 5 Whys method is an excellent tool for team problem-solving. By involving multiple team members in the process, you can get a broader perspective on the issue and come up with more effective solutions.

How to use the 5 Whys method effectively

To use the 5 Whys method effectively, follow these practical tips:

Define the problem clearly

Before you start asking "Why?" five times, make sure you have a clear understanding of the problem you are trying to solve . Be specific about the issue you are trying to address.

Involve the right people

If you are using the 5 Whys method in a team setting, make sure you involve the right people. You want to have a diverse group of individuals with different perspectives and expertise.

Ask open-ended questions

When asking "Why?" make sure you ask open-ended questions that encourage discussion and exploration. Avoid closed-ended questions that limit the conversation.

Avoid blame

The 5 Whys method is not about blaming individuals for problems. Instead, it's about finding the root cause of the issue so that it can be addressed and prevented in the future. Make sure the focus is on finding solutions rather than assigning blame.

Keep it simple

The 5 Whys method should be straightforward and easy to understand. Avoid using technical jargon or complex language that might confuse people.

Use it proactively

The 5 Whys method can also be used proactively to identify potential problems before they occur. By asking "why?" five times, you can uncover potential issues and address them before they become significant problems.

Real-world applications of the 5 Whys method

The 5 Whys method can be used in a wide range of industries and situations. Here are some examples:

Manufacturing

In manufacturing, the 5 Whys method can be used to identify the root cause of defects in products. By doing so, manufacturers can make improvements to their processes and prevent similar defects from occurring in the future.

In healthcare, the 5 Whys method can be used to identify the root cause of medical errors or patient safety incidents. By doing so, healthcare providers can develop processes and procedures to prevent similar incidents from occurring in the future.

In business, the 5 Whys method can be used to identify the root cause of problems such as low employee morale, poor customer satisfaction, or low productivity. By doing so, businesses can make improvements to their processes and address the underlying issues.

The 5 Whys method is a simple yet powerful problem-solving technique that can be used in a wide range of situations.

By asking "why?" five times, you can identify the root cause of an issue and develop effective long-term solutions. When using the 5 Whys method, it's essential to define the problem clearly, involve the right people, ask open-ended questions, avoid blame, keep it simple, and use it proactively.

By following these tips, you can use the 5 Whys method to its full potential and achieve better outcomes in your personal and professional life.

FAQs: 5 Whys

Is the 5 whys method the only problem-solving technique.

No, there are several other problem-solving techniques, such as root cause analysis, fishbone diagrams, and SWOT analysis.

Can the 5 Whys method be used in personal situations?

Yes, the 5 Whys method can be used in personal situations such as identifying the cause of a relationship issue or a personal problem.

How many people should be involved in the 5 Whys method?

It depends on the situation. In some cases, a single person can use the 5 Whys method to solve a problem . In other cases, a team may be required.

How long does it take to complete the 5 Whys method?

It depends on the complexity of the issue being addressed. In some cases, it may only take a few minutes, while in others, it may take several hours.

Is the 5 Whys method foolproof?

No, the 5 Whys method is not foolproof. It is just one tool in a problem-solving toolbox and should be used in conjunction with other techniques.

Additional 5 Why Information

5 Whys Analysis : The 5 Whys analysis is a problem-solving technique that involves asking "why?" five times to uncover the root cause of an issue. It is a simple and effective way to get to the heart of a problem and develop long-term solutions.

5 Whys Template : A 5 Whys template is a tool that can be used to guide the process of asking "Why?" five times. It typically includes spaces to document the answers to each of the five questions and helps to keep the process organized.

5 Whys Example : An example of the 5 Whys technique in action might be investigating why a customer is unhappy with a product or service. By asking "why?" five times, the company could identify the root cause of the issue and take steps to address it.

5 Whys Technique : The 5 Whys technique is a problem-solving method that involves asking "why?" five times to uncover the root cause of an issue. It is a useful tool in a wide range of industries and situations.

5 Whys Method : The 5 Whys method is a structured approach to problem-solving that involves asking "why?" five times to get to the root cause of an issue. It is a simple yet powerful tool that can be used in many different situations.

5 Whys Problem Solving : The 5 Whys problem-solving technique is a way to identify the root cause of an issue by asking "Why?" five times. It is an effective way to get to the heart of a problem and develop long-term solutions.

5 Whys Template Word : A 5 Whys template in Word is a document that can be used to guide the process of asking "why?" five times. It can be customized to suit the needs of a particular situation.

5 Whys Root Cause Analysis Example : A root cause analysis using the 5 Whys method might involve investigating why a manufacturing process is producing defective products . By asking "why?" five times, the root cause of the defects could be identified and addressed.

5 Whys Six Sigma : The 5 Whys technique is a valuable tool in the Six Sigma process, which focuses on improving quality and efficiency in manufacturing and other industries.

Root Cause Analysis 5 Whys Template : A root cause analysis using the 5 Whys method can be facilitated by using a template that guides the process of asking "why?" five times. This helps to keep the process organized and focused.

What are the 5 Whys Questions : The 5 Whys questions are a set of five questions that are used to identify the root cause of a problem. They are typically phrased as "Why did this happen?" and repeated five times.

How are the 5 Whys used : The 5 Whys are used to identify the root cause of a problem by asking "Why?" five times. This helps to get to the heart of the issue and develop long-term solutions.

Jefferson Memorial 5 Whys : The Jefferson Memorial in Washington, D.C. is an example of the 5 Whys technique in action. The memorial was experiencing water infiltration, and the 5 Whys were used to identify the root cause of the problem.

Using the 5 Whys is a Helpful Way to : Using the 5 Whys is a helpful way to get to the root cause of a problem and develop long-term solutions. It is a simple and effective problem-solving technique that can be used in many different situations.

Sakichi Toyoda 5 Whys : Sakichi Toyoda, the founder of Toyota Industries, is credited with developing the 5 Whys technique as a way to improve the company's manufacturing processes. The technique has since been adopted by many other industries and has become a widely used problem-solving method.

Final thoughts

The 5 Whys is a problem-solving technique used to determine the root cause of a problem. It involves asking "why" at least five times to drill down to the underlying issue causing the problem.

For example, if a machine in a factory stopped working, the first "why" could be, "Why did the machine stop working?" The second "why" could be, "Why did the machine's motor fail?" The third "why" could be, "Why was there a short circuit in the motor?" The fourth "why" could be, "Why wasn't the motor properly maintained?" And the fifth "why" could be, "Why wasn't there a regular maintenance schedule for the motor?"

By asking "why" at least five times, the root cause of the problem can be identified, and the necessary actions can be taken to prevent it from happening again in the future.

Recent Posts

TQM: What Is TQM? Total Quality Management Explained

Kaizen: Why Should You Use Kaizen?

Free Web Tools: 150 Free Must-Have Online Tools

- FREE LEAN TOOLS -

"get your free lean tools", kaizen tools.

FEATURED POST

Kaizen: a comprehensive overview, project management.

- About Amy Gray | The Leadership Effect

Individual Leadership Coaching

- Business Coaching

- Master Deep Active Listening Skills for Leaders & Managers

- Coaching Skills for Leaders & Managers

- Course: Team Trust Foundations

- Course: Better 1:1s

- Give Constructive Feedback That Creates An Impact Guidebook

- 9 Critical Thinking Tools Every Effective Leader Needs Guidebook

- Receiving Feedback Webinar

- Giving Feedback Webinar

- Other Recommended Resources

The 5 Whys: Root Cause Analysis

“The most serious mistakes are not being made as a result of wrong answers. The truly dangerous thing is asking the wrong question.” Peter Drucker

In this article, we’ll explore the significance of this problem-solving tool, its applications, and how it can benefit leaders and managers in various organisational contexts.

Table of Contents

How do the 5 whys help leaders and managers.

The 5 Whys technique serves as a powerful ally for leaders and managers seeking to understand the root causes of problems within their organisations. By delving into cause-and-effect relationships through a series of iterative “Why?” questions, this method uncovers the underlying issues that might be overlooked at the surface level.

Let us look at the key benefits of this tool:

- Simplicity, Accessible and Efficient (cost Effective)

- Effective Root Cause Analysis

- Promotes Deeper Understanding

- Encourages Team Involvement

- Focuses on Relationships Between Causes

- Flexibility and Adaptability

- Facilitates Preventative Measures

- Improves Processes and Systems

Simplicity, Accessible and Efficient (cost Effective): One of the primary advantages of the 5 Whys is its simplicity. It does not require statistical analysis or expensive tools. This makes it accessible to a wide range of people within an organisation, regardless of their expertise or technical background. It can also provide insights in a time-efficient manner, which is particularly useful in fast-paced business environments. And, since it doesn’t require special training or tools, it’s a cost-effective method for problem-solving and continuous improvement.

Effective Root Cause Analysis: By continually asking “Why?”, this technique helps to drill down beyond the symptoms of a problem to reach its underlying cause. This can lead to more sustainable and effective solutions, rather than just treating the symptoms. This is okay when it is a simple or complex problem but won’t work on Wicked Problems that are not reductive.

Promotes Deeper Understanding: The process of asking and answering “Why?” multiple times leads to a deeper understanding of the processes and systems within an organisation. This understanding can be valuable in preventing future issues.

Encourages Team Involvement: The 5 Whys can be a collaborative tool, involving different perspectives and expertise. This collective approach not only improves the accuracy of the analysis but also builds a culture of team-based problem solving.

Focuses on Relationships Between Causes: By asking why repeatedly, the method not only identifies root causes but also helps in understanding the relationships between different causes of a problem.

Flexibility and Adaptability: The 5 Whys is a versatile tool that can be applied in a wide range of contexts, from manufacturing and engineering to human resources and administration.

Facilitates Preventative Measures: Understanding the root cause of a problem enables an organisation to develop strategies to prevent similar issues in the future.

Improves Processes and Systems: By identifying and addressing systemic issues, the 5 Whys can lead to long-term improvements in organisational processes and systems.

How To Use The 5 Whys?

Simplicity, accessibility, and efficiency.

The fundamental idea is that by repeatedly asking the question “Why?”—usually five times—you can peel away the layers of symptoms and arrive at the root cause of a problem.

The effectiveness of the 5 Whys relies on the skill with which the questions are asked and the honesty and accuracy of the answers.

It’s often used in conjunction with other tools and techniques for a more comprehensive analysis.

For example, it might be combined with a fishbone diagram to provide a more visual representation of the cause-and-effect relationships.

It is a valuable tool for any organisation seeking a straightforward, collaborative, and effective approach to root cause analysis

What are the Key Challenges when Implementing The 5 Whys

Perceived Blame: Team members may feel like they are being blamed for problems, especially if the questioning seems to point towards individual actions or decisions.

Defensiveness: Feeling put on the spot can lead to defensiveness, hindering open and honest communication.

Oversimplification: There’s a risk of oversimplifying complex problems, leading to incorrect root cause identification.

Lack of Depth in Answers: Without thorough investigation, responses might be superficial, missing deeper systemic issues.

Confirmation Bias: There’s a tendency to stop at an answer that confirms pre-existing beliefs or assumptions.

Variable Skill Levels: The effectiveness of the 5 Whys can depend heavily on the skill of the person leading the session.

How to Overcome The Challenges of The 5 Whys

Setting the Right Tone: Begin by emphasising that the process is about identifying process issues, not blaming individuals. Make it clear that the intent is to improve the system as a whole.

Create a Safe Environment: Establish a non-threatening environment where team members feel safe to share honest feedback without fear of retribution.

Focus on Processes, Not People: Frame questions in a way that focuses on processes and systems. For example, instead of asking why a salesperson failed to do X, ask what in the process might have led to this oversight.

Encourage Participation: Make it a collaborative effort. Encourage everyone to contribute their perspective, emphasising that all viewpoints are valuable.

Educate About the Technique: Explain the purpose and method of the 5 Whys to the team, so they understand it’s a problem-solving tool, not a fault-finding exercise.

Use Facilitation Skills: The facilitator should be skilled in guiding the conversation, keeping it on track, and digging deeper without making it personal.

Seek Comprehensive Solutions: Look for solutions that address the root cause comprehensively, rather than quick fixes.You may run the 7 So What’s on a potential solution to test any issues.

Document and Reflect: Write down the responses and reflect on them later. This can help in identifying patterns that might not be evident at the moment.

Follow-Up: After implementing changes, monitor the results and be prepared to revisit the analysis if the problem persists.

Case Studies: Using The 5 Why’s In Business

Scenario 1: invoicing and billing problems in a company.

Problem Description: A company is experiencing invoicing and billing problems, which are causing delays in processing payments.

- Answer : The data needed for invoicing is not being received on time.

- Answer: Contracts vary across different business units, leading to inconsistencies in data collection.

- Answer: Each proposal leads to a new contract being drafted.

- Answer: We have to try and locate and reuse previous documents but that’s time consuming

- Answer: There’s no common repository for document storage and no standard procedure for document retrieval or document tagging)

Root Cause: The root cause of the invoicing and billing problems is the absence of a centralised document management system and standardised processes for contract creation and data collection. This may lead to the company deciding on core templates being created, tagged and stored in a central area

Scenario 2: High Employee Turnover in a Sales Department

Problem Description: A company’s sales department is facing a high rate of employee turnover.

- Answer: Sales employees are leaving due to job dissatisfaction.

- Answer: They feel that their performance targets are unrealistic and stressful.

- Answer: Targets are set without considering market conditions and individual capabilities.

- Answer: There’s a lack of communication between sales employees and management.

- Answer: The company lacks a formal process for feedback and discussion regarding target setting.

Root Cause: The high employee turnover in the sales department is rooted in the absence of a structured communication and feedback mechanism for realistic target setting, leading to job dissatisfaction among sales employees.

It’s evident that the 5 Whys is simple, effective, and adaptable making it a valuable asset for organisations committed to continuous improvement and problem-solving. By overcoming challenges and promoting a collaborative approach, the 5 Whys proves itself as a timeless tool in the hands of leaders and managers striving for organisational excellence.

Do you want more information about our courses on Coaching Skills for Leaders? Click here .

Drowning in Details & Meetings? The Leader’s Guide to Breaking Free from Operational Quicksand

The art of delegation empowering your team and elevating your leadership part 2 of 2, from bottleneck to breakthrough: a leader’s guide to trust and delegation part 1 of 2, leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Leadership Development Programs

About Amy Gray

Subscribe To Our Mailing List

Privacy Policy

Corporate Policies and Statements

Articles & Insights

Client Stories & Results

- Recommended Resources

Ebook: How To Give Feedback

Sydney, Australia

LinkedIn: Amy Gray

Instagram: @LeadershipEffect

- Programs & Courses

- Client Stories

© The Leadership Effect All rights reserved.

Critical Thinking Via 5 Whys and First Principles

This technique can work well (here’s a real-world example from a kitchen range manufacturer) but has its limitations. In a complex situation, you can suffer from tunnel vision which might lead to an incorrect conclusion. To counteract this, there are variants of the 5 Whys technique which intentionally create branches (alternative theories) and therefore explore new ground. In mathematics this is called avoiding a local maximum to search for a global maximum. For those interested in learning more, here’s a good article on variants of the 5 Whys technique.

The recent Elon Musk-fueled craze around first principle thinking reminded me that everything old is new again. First principle thinking, for those who haven’t seen the endless articles trumpeting this breakthrough, is a mode of thinking “designed to relentlessly pursue the foundations of any given problem from fundamental truths.” In science, theoretical work is considered to be from first principles if it starts directly with established science and doesn’t rely on assumptions. This approach isn’t really new: A case can be made it originated more than 2000 years ago with Aristotle.

Confused? Here’s a frequently-referenced video of Elon describing how first principles thinking challenged the traditional economics of making batteries:

5 Whys and First Principles are both examples of critical thinking but differ in how they approach the problem. 5 Whys is top down; starting with the observed result and trying to discover the underlying cause. On the other hand, the First Principles approach builds from basic truths to discover new solutions. Each has merit and is appropriate in different circumstances. When in doubt, try them both.

Regardless of which approach you use, the key to critical thinking is to be sensitive to your built-in biases and learn to challenge surface explanations. Be sure to ask more questions; just remember it’s hard to ask good questions .

5 Whys , critical thinking , Elon Musk , First Principles

Trackbacks/Pingbacks

[…] I want to reinforce the need for critical thinking, I sometimes bring up the green coffee bean […]

Leave a Reply Cancel reply

Copy short link.

5 Whys: How to Uncover Root Causes [Examples]

By Status.net Editorial Team on May 18, 2023 — 11 minutes to read

The Five Whys technique is a simple and effective tool for identifying the root cause of an issue by asking “why” repeatedly (up to five times) to dig deeper into the underlying causes of a problem and to uncover the chain of events leading up to it. Developed by Sakichi Toyoda, the founder of Toyota Industries, this approach has become an essential part of problem-solving and continuous improvement in various industries.

By asking “why” multiple times, the Five Whys method helps us avoid settling for surface-level explanations, which can often hide the true causes of a problem. This technique promotes a culture of curiosity and encourages teams to collaboratively explore all possible answers until the core issue becomes evident. In turn, this allows for the development of effective and targeted solutions, resulting in long-lasting improvements rather than temporary fixes.

For example, consider a scenario where the production line in a factory has slowed down significantly. By employing the Five Whys technique, the team might discover that faulty machinery is the immediate issue (first “why”). Further investigation might reveal a lack of maintenance as the cause (second “why”). After a few more iterations, the team might uncover a gap in training for maintenance workers (fifth “why”) as the root cause, which can then be addressed by implementing a comprehensive training program.

Related: Root Cause Analysis (RCA) Methods for Effective Problem Solving 3 Root Cause Analysis Templates (and Examples) Fishbone Diagram (Components, Factors, Examples)

History of Five Whys

The Five Whys technique has its roots in the Toyota Production System, developed by Sakichi Toyoda, the founder of Toyota Motor Corporation. Sakichi believed that by asking “Why?” repeatedly, one could identify the core of any problem and develop effective solutions. This approach was later refined and promoted by Taiichi Ohno, known as the father of the Toyota Production System.

In its early days, the Five Whys method was adopted by Toyota to improve its manufacturing processes and eliminate waste, contributing significantly to the company’s global success. By implementing this simple yet powerful approach, Toyota was able to identify root causes of recurring issues and develop long-term, sustainable solutions.

Over time, the Five Whys technique has gained popularity beyond its use within the automotive industry. Today, it is employed in various fields and organizations as a valuable problem-solving tool. Its effectiveness stems from its simplicity, allowing individuals and teams to quickly identify, understand, and address the underlying causes of an issue, rather than merely treating the symptoms.

Here are some examples of the Five Whys in action:

- Example: A production line stops unexpectedly.

- Why did the line stop? The machine overheated.

- Why did the machine overheat? The coolant pump failed.

- Why did the coolant pump fail? It was not maintained properly.

- Why was it not maintained properly? There was no scheduled maintenance plan.

- Why was there no maintenance plan? The necessity of regular maintenance was not recognized.

- Example: A digital marketing campaign fails to generate leads.

- Why didn’t the campaign generate leads? The target audience didn’t engage with the ads.

- Why didn’t the target audience engage with the ads? The ad creative was not compelling.

- Why wasn’t the ad creative compelling? It didn’t resonate with the audience’s interests.

- Why didn’t it resonate with the audience’s interests? Market research was not conducted.

- Why wasn’t market research conducted? The project timeline was too tight.

- Example: A software application experiences frequent crashes.

- Why does the application crash? There are several bugs in the code.

- Why are there bugs in the code? The testing process was inadequate.

- Why was the testing process inadequate? The test cases were not comprehensive.

- Why were the test cases not comprehensive? The testing team was understaffed.

- Why was the testing team understaffed? The importance of thorough testing was not prioritized.

Understanding the Five Whys Process

Root cause analysis.

The Five Whys process is a practical approach to root cause analysis. Its primary goal is to identify the underlying cause of a problem, rather than fixing it temporarily.

The process begins by stating the problem, followed by asking “why” the problem exists. Each successive answer becomes the subject of the next “why” question until the root cause is identified. Typically, five questions are sufficient, although more or fewer may be necessary depending on the situation. The Five Whys process encourages open communication and collaboration among team members in order to effectively solve problems.

Iterative Interrogative Technique

The iterative interrogative technique in the Five Whys process promotes continuous improvement by emphasizing critical thinking. It helps team members to approach problem-solving with a clear mindset, focusing on the reasons for the problem instead of quick fixes. Continuous improvement is vital for maintaining a high level of performance in any organization.

Throughout the process, team members should be encouraged to ask questions and contribute their perspectives. This dialogue fosters a culture of learning and improvement where everyone’s input is valued. Note that it is important to keep an open mind and focus on facts rather than assumptions when seeking the root cause of a problem.

- Root cause: The organization needs to find ways to increase revenue to hire more staff and reduce wait times for customers.

- Root cause: Implement a clear maintenance schedule and provide additional support for the maintenance team to prevent machine breakdowns.

- Root cause: Improve project management and communication to ensure that deadlines are met.

Five Whys in Decision-Making

Using the Five Whys technique in decision-making enables a more comprehensive analysis by encouraging reflection on multiple facets of an issue. It highlights the value of understanding the root causes before finalizing decisions, which can result in more informed and deliberate choices.

The benefits of using the Five Whys in decision-making include better allocation of resources, enhanced problem-solving skills, and more sustainable solutions to challenges. Through this method, decision-makers can effectively address recurring problems, reducing the likelihood of similar issues in the future.

Example 1: A project is continually behind schedule, which impacts profitability.

- Why is the project behind schedule? The team is constantly missing deadlines.

- Why is the team missing deadlines? They are struggling with workload prioritization.

- Why are they struggling with workload prioritization? There is a lack of clear project milestones.

- Why are there no clear project milestones? The project manager lacks experience in defining them.

- Why does the project manager lack experience? They were promoted without proper training. Decision: Implement project management training for the project manager and establish clear milestones for the team to follow.

Example 2: Customer complaints have increased in recent months, affecting brand reputation.

- Why have customer complaints increased? Wait times for service have increased.

- Why have wait times increased? There is a shortage of staff during peak hours.

- Why is there a staff shortage during peak hours? Current scheduling does not account for demand fluctuations.

- Why doesn’t scheduling account for demand fluctuations? The scheduling system is outdated and inefficient.

- Why is the scheduling system outdated and inefficient? There has been a lack of investment in technology. Decision: Invest in a new scheduling system to improve staff allocation during peak hours, reducing wait times and enhancing customer satisfaction.

Example 3: Product defects have led to a decline in sales and an increase in returns.

- Why are there product defects? Quality control measures are insufficient.

- Why are quality control measures insufficient? The current procedures are not comprehensive enough.

- Why aren’t the procedures comprehensive enough? There’s no dedicated quality control team.

- Why is there no dedicated quality control team? The company hasn’t prioritized quality management.

- Why hasn’t the company prioritized quality management? The focus has been on cost reduction instead. Decision: Allocate resources to establish a dedicated quality control team and implement more robust procedures to address product defects and ensure customer satisfaction.

The Role of Five Whys in Process Improvement

The Five Whys technique is an essential tool for effective process improvement in various industries. Primarily used in Lean Manufacturing, Six Sigma, and Kaizen methodologies, it helps to identify root causes of problems and fosters continuous and quality improvement. The purpose of Five Whys is to prevent issues from recurring and make informed decisions for sustainable enhancements in performance.

When implementing continuous improvement practices, it is important to understand that issues often have deeper underlying causes than what appears on the surface. The Five Whys method encourages identifying these causes through an iterative, question-based process to reveal the true origin of the problem.

A common application of Five Whys is in quality improvement initiatives, where the technique ensures that improvements focus on addressing the root cause of a defect rather than just the symptoms. This fundamental approach helps organizations eliminate waste and inefficiencies in their processes and systems.

Criticisms and Limitations of the Five Whys

Human factor.

The Five Whys technique relies heavily on people’s ability to accurately identify root causes, which can be influenced by personal bias or lack of expertise. This may lead to incorrect conclusions and can potentially hinder problem-solving efforts. Moreover, the technique does not account for complex issues with multiple root causes or unknown factors, which may require a more comprehensive approach.

For example, in a manufacturing setting, the reason for a machine malfunction might not be immediately apparent. A human operator might mistakenly attribute the issue to a single cause, such as inadequate maintenance, while ignoring other factors, such as equipment age or external influences like temperature fluctuations.

Overemphasis on Blame

The Five Whys approach can unintentionally create a focus on blaming individuals, teams, or departments for identified issues instead of fostering a culture of continuous improvement and shared responsibility. By repeatedly asking why, team members might feel that they are being interrogated and may become defensive, affecting morale and trust .

Other Problem-Solving Techniques

Fishbone diagram.

The Five Whys technique and the Fishbone Diagram both serve as problem-solving methodologies, but they have distinct differences. The Fishbone Diagram, also known as the cause-and-effect diagram, is a visual tool that illustrates the possible causes of a specific problem. It helps identify, sort and categorize these possible causes across several aspects, such as materials, equipment, process or people. It’s often used in engineering or manufacturing to pinpoint the root cause of defects.

The Five Whys technique relies on asking a series of “why” questions. This method digs deeper into cause-and-effect relationships to uncover hidden issues or underlying factors that contribute to the problem.

- Example 1: In a manufacturing process, there’s a high scrap rate. While Fishbone Diagram may identify multiple causes such as machine inaccuracy, employee skills, and poor materials, the Five Whys can dig deeper to find issues such as lack of problem-solving training.

- Example 2: In an engineering project, delays keep happening. Fishbone Diagram may point to factors like resource constraints, human error, and communication breakdowns, while the Five Whys could uncover that the project manager isn’t taking proactive countermeasures to manage risks.

Learn more: Fishbone Diagram (Components, Factors, Examples)

Ishikawa Diagram

An Ishikawa Diagram is essentially another name for a Fishbone Diagram. It is so called because it was developed by Dr. Kaoru Ishikawa, who pioneered quality management processes in the Kawasaki shipyards. Just like the Fishbone Diagram, it serves as a visual representation of possible causes of a problem and categorizes them into various aspects, making it easier for the team to identify and address the root cause.

Compared to the Five Whys technique, the Ishikawa Diagram focuses on visually organizing causes, which can be particularly useful for complex problems with multiple factors. The Five Whys, while more straightforward, encourages a deeper understanding of the problem through a series of questions to uncover the root cause.

- Example 1: A car manufacturing company faces frequent equipment breakdowns. An Ishikawa Diagram can categorize this issue under several factors like machinery, workforce, and maintenance, while the Five Whys could reveal that the company is not conducting regular inspections.

- Example 2: A software company experiences a high rate of bugs in their projects. The Ishikawa Diagram might highlight issues related to design, coding, and testing, whereas the Five Whys can identify that the team is not using a proper defect tracking system.

Learn more: Ishikawa Diagram: Examples and Applications

Poka-Yoke is a Japanese term that translates to “mistake-proofing” or “error-proofing.” It’s a concept that focuses on preventing errors by designing processes and systems to eliminate human error or reduce its impact. Unlike the Five Whys technique, which aims to identify the root cause of a problem after it has happened, Poka-Yoke is a proactive approach to ensure that defects do not occur in the first place.

The Five Whys technique can complement Poka-Yoke by helping organizations understand how their processes have failed and subsequently implementing error-proofing measures based on the identified root causes.

- Example 1: A packaging company has inconsistent sealing quality on their products. The Five Whys might reveal that the cause is the sealing machine’s varying temperatures, leading to the implementation of Poka-Yoke by installing an automatic temperature control system.

- Example 2: A hospital faces cases of wrong medication being given to patients. Using the Five Whys may uncover that the issue is due to human error, leading to a Poka-Yoke solution, such as implementing barcode scanning to verify medication assignments.

Learn more: What is Poka-Yoke? (Examples, Principles, Methods)

- Ishikawa Diagram: Examples and Applications

- 3 Root Cause Analysis Templates (and Examples)

- Fishbone Diagram (Components, Factors, Examples)

- Root Cause Analysis (RCA) Methods for Effective Problem Solving

- Self Evaluation Examples [Complete Guide]

- What is Poka-Yoke? [Examples, Principles, Methods]

5 Whys Technique: Uncover Root Causes

- Problem Solving

What is 5 Whys?

The 5 Whys is a simple yet powerful problem-solving method designed to uncover the root cause of an issue by asking “why” multiple times—usually five.

The concept is simple: when faced with a problem, you ask “why” it occurred, and then continue asking “why” to each subsequent answer, ideally five times or until you reach a fundamental cause.

This process continues until you identify the fundamental cause.

Why Use the 5 Whys?

The 5 Whys technique is valuable because it digs deeper into the problem, helping you move past surface-level symptoms to understand the core issue.

This approach leads to more effective solutions and helps prevent the problem from recurring in the future.

Origins of the 5 Whys

The 5 Whys technique is often associated with Sakichi Toyoda, the founder of Toyota Industries.

It was developed as part of the Toyota Production System (TPS), a system famous for its emphasis on continuous improvement.

While Toyota popularized the technique in manufacturing, similar problem-solving methods have been used across various industries.

Example of 5 Whys in Action

Here’s an example to illustrate:

Problem: The production line stopped working.

- Why did the production line stop? – Because the machine was overheated.

- Why did the machine overheat? – Because the cooling system failed.

- Why did the cooling system fail? – Because the pump stopped working.

- Why did the pump stop working? – Because it wasn’t maintained regularly.

- Why wasn’t the pump maintained regularly? – Because there wasn’t a scheduled maintenance plan in place.

In this example, the root cause of the production line stopping is identified as the lack of a maintenance plan. By addressing this root cause, future issues with the production line can potentially be prevented.

Unlock all frameworks and templates

Unlock exclusive thinking frameworks and practice templates. Become a member now to access all premium content to elevate your thinking!

Benefits of the 5 whys

Identifying Root Causes

By repeatedly asking “why,” the technique helps to uncover the underlying reasons behind a problem rather than just addressing its symptoms. This allows organizations to tackle issues at their core, leading to more effective solutions.

Encouraging Critical Thinking

The 5 Whys technique encourages a deeper level of analysis and critical thinking by challenging assumptions and exploring causal relationships. It prompts individuals and teams to look beyond obvious explanations and consider interconnected factors.

Simple and Cost-Effective

The method is straightforward and easy to understand, requiring minimal resources to implement. It doesn’t rely on complex tools or technology, making it accessible to organizations of all sizes.

While the technique is called “5 Whys,” the number of iterations isn’t fixed. Sometimes, the root cause may be identified in fewer or more than five iterations. The goal is to continue asking “why” until reaching a point where further questioning doesn’t yield meaningful insights.

Get Your Free Newsletter

Subscribe to our newsletter and g et FREE ready-to-use templates to enhance your capabilities.

We won't send you spam. Unsubscribe at any time.

Check your inbox or spam folder to confirm your subscription.

- Problem-Solving Trouble-Shooting

More frameworks

FMEA Methodology: Identify Failure Modes and Priotirize Risks

Identify failure modes and prioritize risks.

Fishbone Diagram: A Simple Guide Helps You Uncover Root Causes

A simple yet powerful tool that helps you analyze and solve problems in a structured way.

- Agriculture

- B2B Services

- Financial Services

- Gaming & Entertainment

- Hospitality

- Social & Public Sector

- Sports & Recreation

- Technology & Telecommunication

- Strategic Planning

- Business Process Analysis

- Performance Improvement

- Market Research and Analysis

- Mergers and Acquisitions

- Risk Management

- Change Management and Implementation

- Organisational Design and Structure

- Financial Analysis and Modelling

- Technology and Digital Transformation